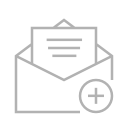

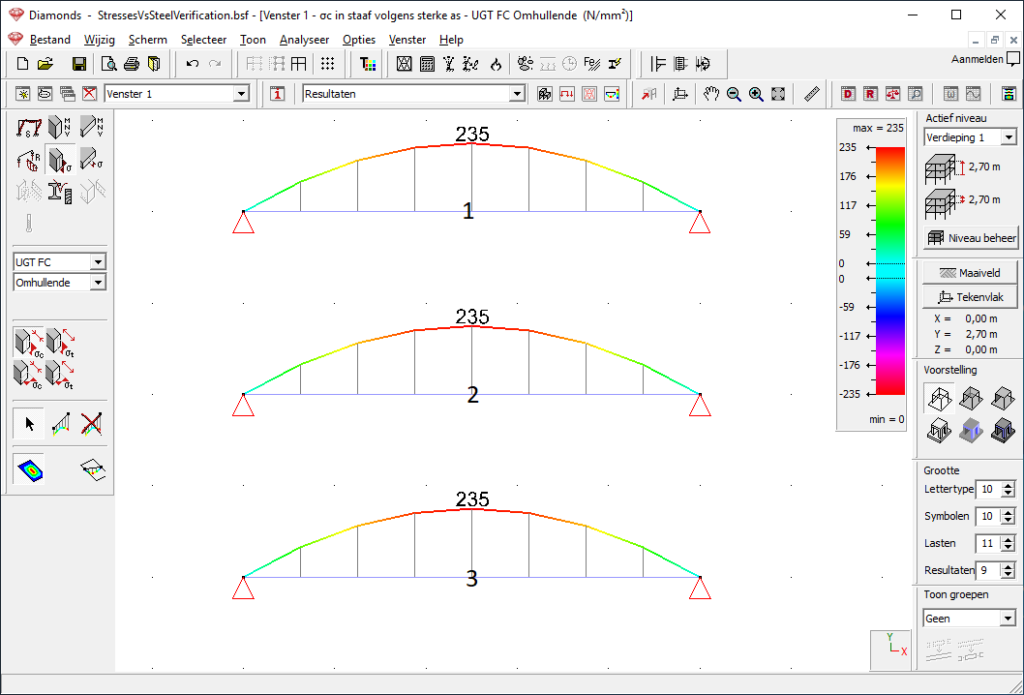

The image below shows the tensile stress and the steel verification for 3 different beams:

- For Beam 1: based on the stresses, you’d expect a steel verification of 100%. But the steel verification is lower.

This is because Diamonds shows the elastic stresses (calculated with Wel), while this section is of class 1 and thus plastic properties (Wpl > Wel) will be used in the steel verification. - For Beam 2: based on the stresses, you’d expect a steel verification of 100%. And indeed, the steel verification is 100%.

This is because Diamonds shows the elastic stresses and this section is of class 3 (Wel) will be used in the steel verification. - For Beam 3: based on the stresses, you’d expect a steel verification of 100%, but the steel verification is higher.

This is because Diamonds shows the elastic stresses (calculated with Wel), while this section is of class 4 and thus effective properties (Weff < Wel) will be used in the steel verification.

So, it is important to do a steel verification because:

- the stresses shown in the global window in Diamonds, are stresses caused by axial force and bending around the z’ OR y’-axis.

It neglects shear, torsion, the risk of instabilities and combinated forces (like N + V + M or N + M + M). - Diamonds shows elastic stresses.

Note: it is not possible to show the stresses according to the Von mises criterium in Diamonds.