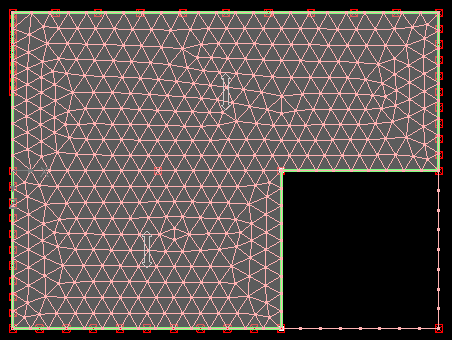

Diamonds is FEM software. That means the structure will be chopped into smaller pieces ( = the mesh), that are logically linked together. The quality of the results, goes with the quality of the mesh. Garbage in = garbage out. So

- first you generate the mesh using logical sizes (see below)

- second you should verify the used mesh size!!

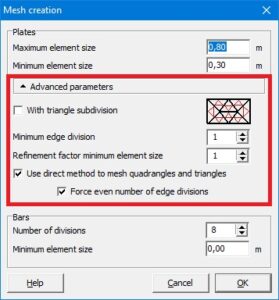

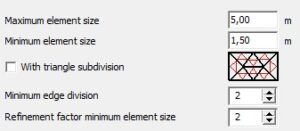

The mesh window ![]() consists of two parts: one for plates and one for bars.

consists of two parts: one for plates and one for bars.

Plates

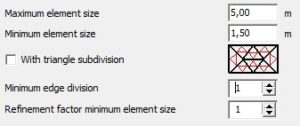

- Maximum element size: 3 to 4 times the plate thickness

The maximum element size determines the general fineness of the mesh.Maximum element size: 0,6m Maximum element size: 0,8m Maximum element size: 1,0m

- Minimum element size: 1,5 to 2 times the plate thickness

The minimum element size determines the fineness of the mesh around small lines and points that are very close to each other (see ‘Step 2’).Don’t set the minimum element size equal to the maximum element size. Only for standard models (like a 4 sided supported plate) a minimum element size of 0m is acceptable.

These parameters are hidden for a reason: only in specific cases it is relevant to change them!

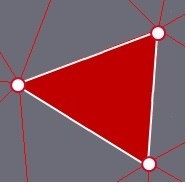

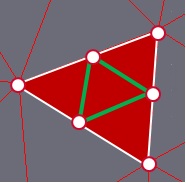

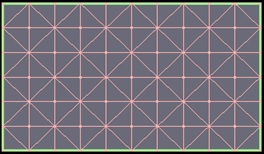

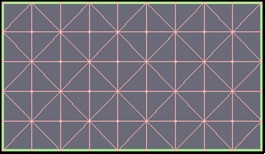

- With triangle subdivision

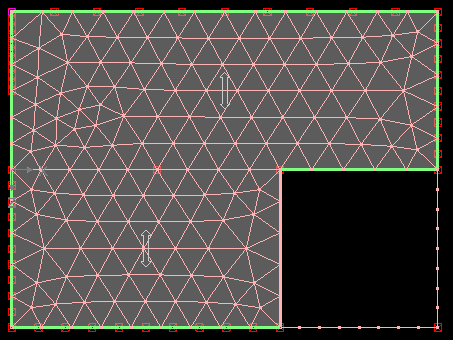

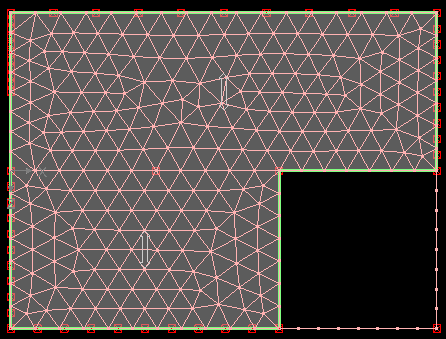

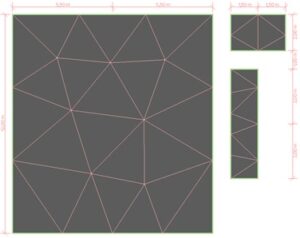

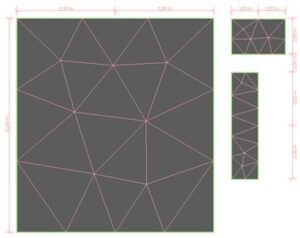

Checking this option will create a smaller mesh with unmodified minimum and maximum elements sizes by connection the mid points on each mesh triangle side.Without triangle subdivision With triangle subdivision

In times when it took a while to generate this mesh, this option had his advantages. But in current times this option has less advantages, because badly chosen min/max element size will result in an even worse mesh when you check this option. If you want a smaller mesh, simply change the min/max element size. In calculation time it will not make a difference, but in the quality of the result it will.

- Minimum edge division (= the numer of mesh points along the boarder of a plate/wall) and refinement factor (= the number of mesh point in the field of a plate/wall)

A good mesh size for the floors, can be too coarse for some walls. Setting the mesh size smaller, will give a good smaller mesh in those walls, but will be too fine in the floors. By increasing both parameters simultaneously, you can obtain a good mesh those smaller walls.

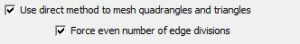

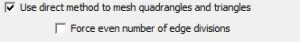

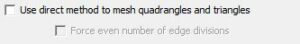

- Options to determine the mesh algorithm

(default option)

(default option)

Bars

- Number of divisions: 8 recommended

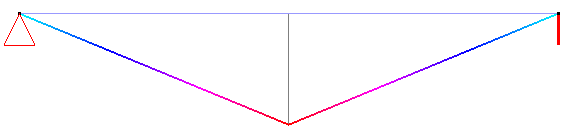

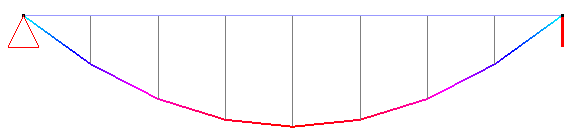

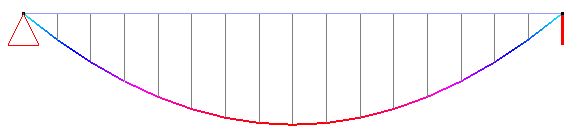

A beam is simply supported and loaded with self-weight. The shape of the moment line is parabolic.2 divisions 4 divisions 8 divisions 16 divisions

With 8 divisions the parabolic shape is well approximated.

- With more divisions the calculation time will increase, while the results don’t benefit.

- With less divisions the calculation time will decrease, but the parabolic shape will be less detailed.

In larger models (with bars mainly loaded with axial force), the number of divisons can be set 4 or 6 divisions to limit the calculation time.

- Minimum element size: 0,1m recommended

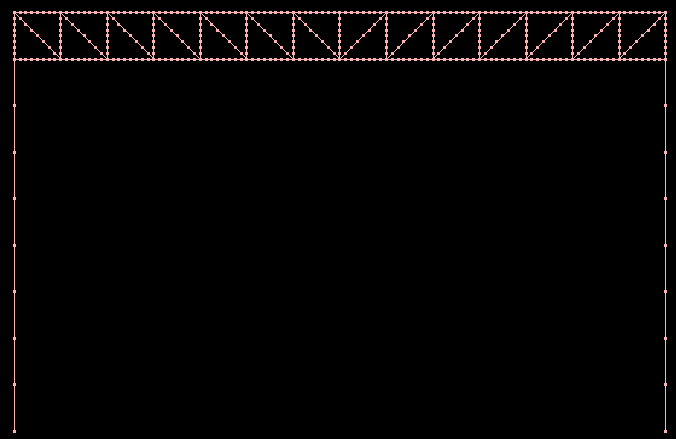

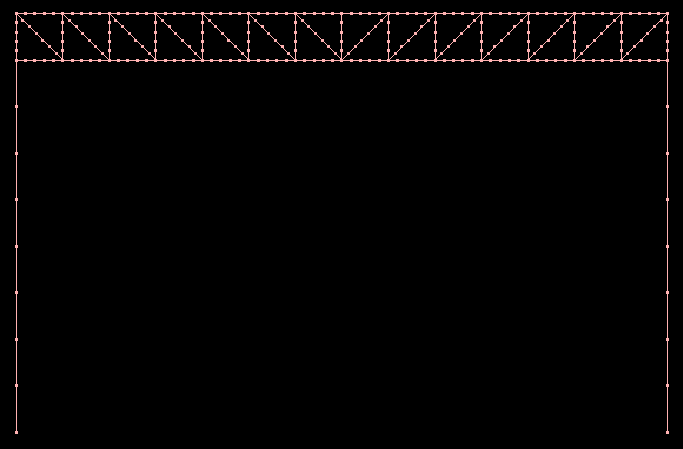

With the minimum element size, you can request less divions in shorter bars.8 divisions + minimum element size: 0,0m 8 divisions + minimum element size: 0,1m

- With a minimum element size equal to 0,0m, all bars have the same number of divisions (8), regardless their length.

- With a minimum element size equal to 0,1m, the number of mesh elements in the shorter beams is reduced. Resulting in less calculating time. Since the complete behaviour of the truss is imported and not the behaviour of every bar seperatly, the mesh shouldn’t be so detailed.